The Future of Hydraulic Pressure Relief Valve Innovations

The hydraulic pressure relief valve is a critical component in hydraulic systems, ensuring safety and efficiency by preventing excessive pressure build-up. According to a report from Grand View Research, the global hydraulic components market is projected to reach $63.1 billion by 2027, with a significant share attributed to advancements in pressure relief valve technology. Innovations in materials and design are paving the way for more reliable and responsive hydraulic pressure relief valves, which are essential for the performance of industrial machinery and equipment. As industries strive for improved safety standards and operational efficiency, the demand for sophisticated hydraulic pressure relief valves is set to increase. This blog will explore the future innovations in hydraulic pressure relief valves, focusing on key trends and technologies that are shaping their development in the coming years.

Innovative Technologies Transforming Hydraulic Pressure Relief Valves

The advancement of hydraulic pressure relief valves is poised to significantly enhance the efficiency and safety of hydraulic systems across various industries. Recent studies have focused on the implementation of innovative technologies such as proportional directional control valves (PDCVs), which enable precise velocity control in applications like hydraulic erection beams. By optimizing the performance of these systems, industries can minimize energy consumption and improve operational reliability, leading to increased productivity and reduced downtime.

Moreover, the pressure safety valve market is projected to witness substantial growth, expanding from USD 4.76 billion in 2024 to an estimated USD 6.94 billion by 2034. This growth is fueled by the rising demand for advanced pressure management solutions in water distribution systems. Innovative algorithms for positioning pressure relief valves are being developed to ensure optimal placement and settings, enhancing the efficiency of water distribution networks while addressing safety concerns. Such technological advancements not only meet current industry needs but also pave the way for future innovations in hydraulic pressure relief systems.

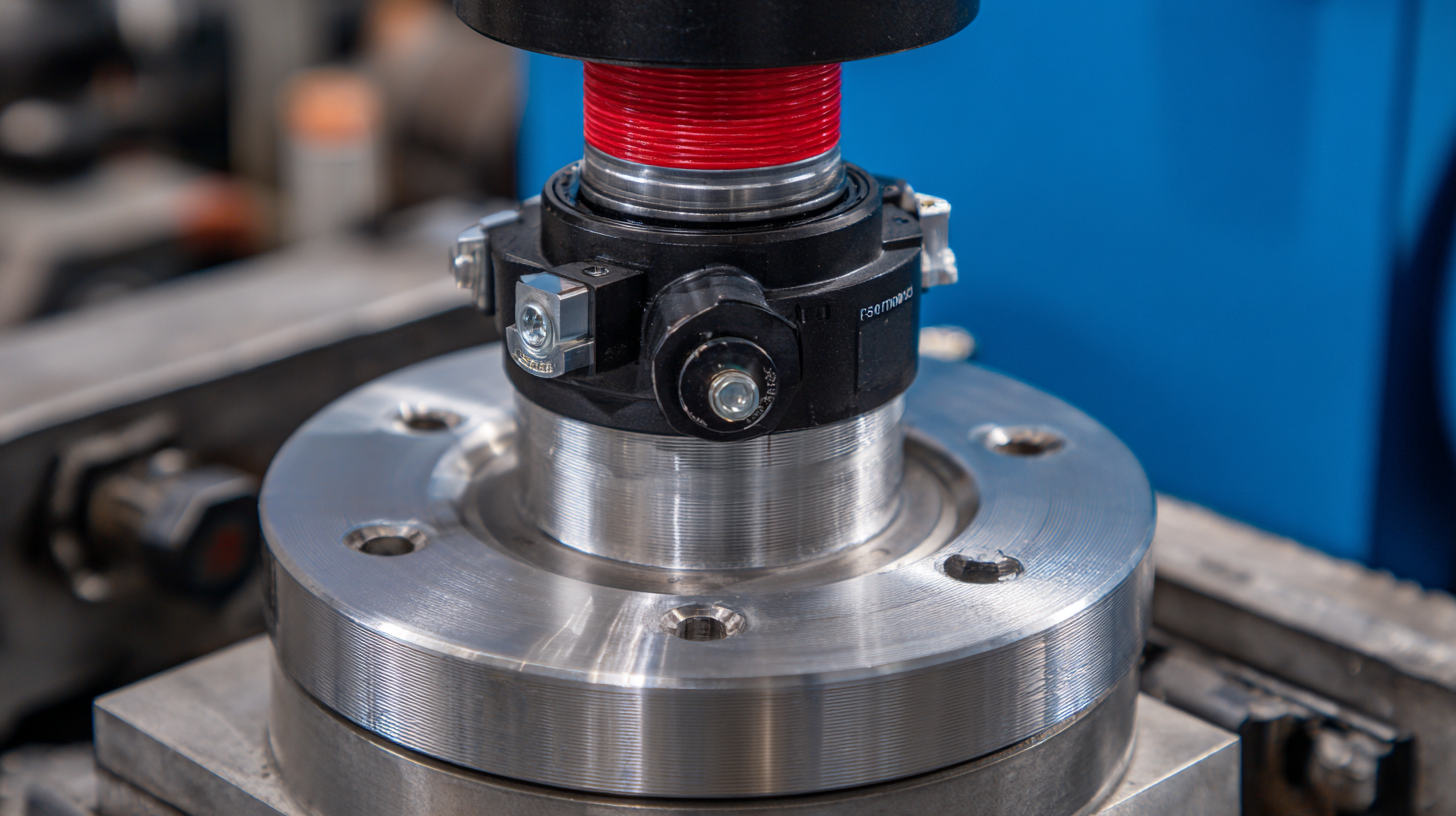

Key Types of Hydraulic Pressure Relief Valves and Their Applications

In the world of hydraulic systems, pressure relief valves play a crucial role in maintaining optimal performance and safety. Key types of hydraulic pressure relief valves include direct-acting valves, pilot-operated valves, and electro-hydraulic valves, each serving specific applications across various industries.

Direct-acting valves are preferred for their simplicity and quick response times, making them ideal for small systems. In contrast, pilot-operated valves are better suited for larger systems, providing improved flow capacity and stability. The rise of electro-hydraulic shift valves has brought about innovations in power-shift steering transmissions, allowing for more precise control and efficiency in heavy machinery.

Tips: When selecting a hydraulic pressure relief valve, consider the specific flow rates and pressure requirements of your application. Monitoring system performance through advanced sensor technologies can significantly reduce the risk of cavitation, enhancing the longevity of your valves.

According to recent market research, the global electrohydraulic servo valve market is projected to grow at a rate of 5.9%, reflecting the ongoing demand for these advanced control solutions in various engineering applications. Stay updated on the latest innovations and maintenance strategies to ensure your hydraulic systems remain efficient and reliable.

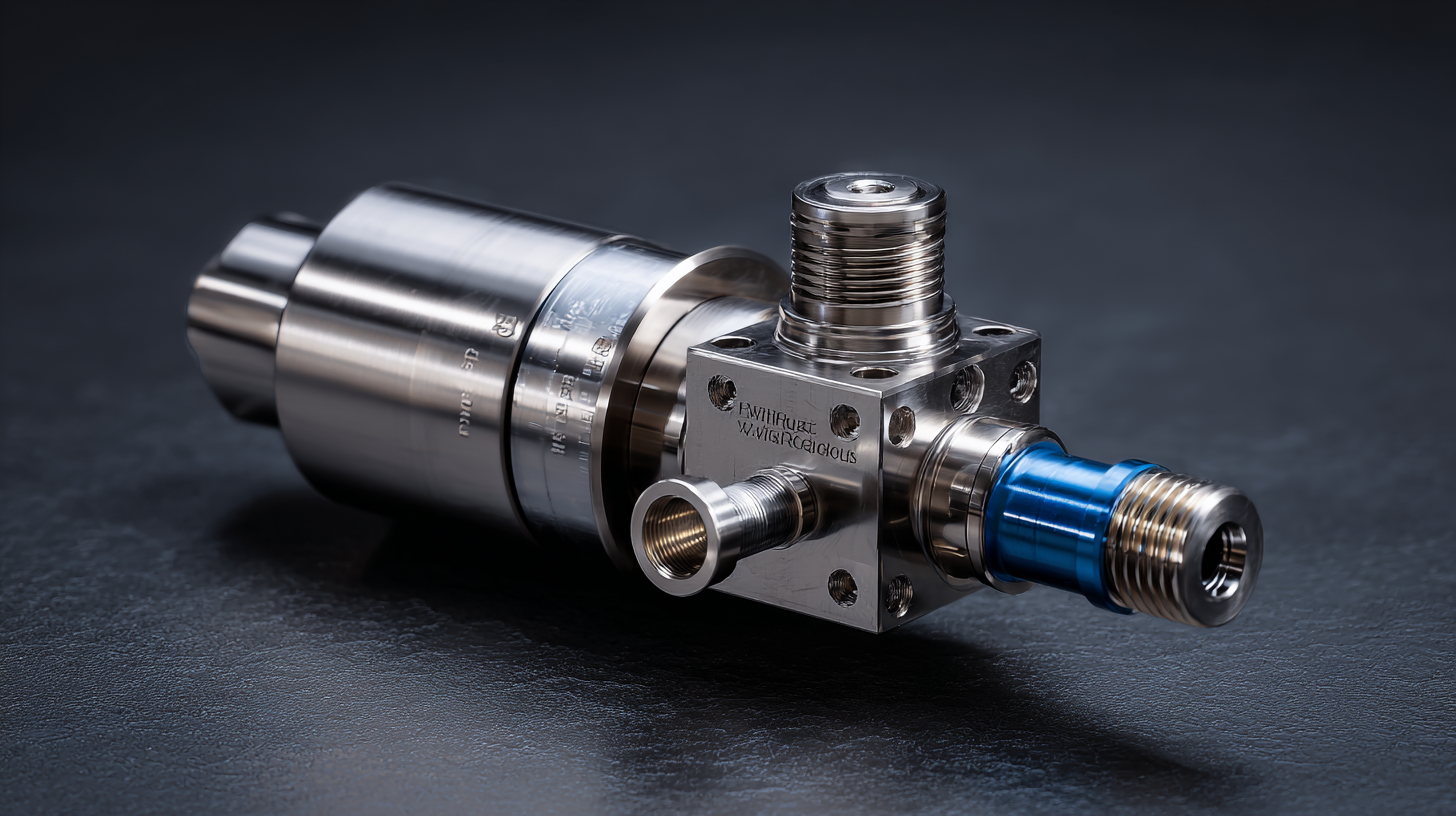

Advancements in Materials Enhancing Valve Performance and Durability

The hydraulic pressure relief valve is a crucial component in various industrial applications, ensuring system safety and efficiency by preventing overpressure conditions. Recent advancements in materials science have paved the way for improved valve performance and durability. Innovations such as advanced polymers and composite materials are being employed to enhance the resilience of these valves against wear and environmental factors, significantly extending their lifespan and reliability.

Moreover, new manufacturing techniques, including 3D printing and laser sintering, allow for the creation of complex geometries that were previously unattainable with traditional methods. These techniques enable the integration of lightweight and corrosion-resistant materials, optimizing the performance of hydraulic pressure relief valves. As a result, operators can expect not only reduced maintenance costs but also improved overall system efficiency. The ongoing research into smart materials that can adapt to changing pressures and temperatures will further revolutionize the landscape, making hydraulic systems more responsive and efficient than ever before.

Future Trends in Smart Hydraulic Pressure Relief Valve Systems

The landscape of hydraulic pressure relief valve systems is undergoing a transformative shift, driven by the integration of smart technologies. Future trends suggest a move towards more intelligent and responsive systems that not only enhance safety but also improve efficiency in hydraulic applications.

These smart valves are equipped with sensors and IoT capabilities that allow for real-time monitoring and data analysis, enabling operators to anticipate potential issues before they escalate. This proactive approach not only minimizes downtime but also extends the lifespan of hydraulic equipment.

These smart valves are equipped with sensors and IoT capabilities that allow for real-time monitoring and data analysis, enabling operators to anticipate potential issues before they escalate. This proactive approach not only minimizes downtime but also extends the lifespan of hydraulic equipment.

Moreover, the implementation of machine learning algorithms in hydraulic pressure relief systems promises to optimize performance further. By analyzing data patterns, these systems can adjust settings dynamically, ensuring optimal pressure management under varying operational conditions. This adaptability is particularly crucial in industries where hydraulic systems must respond to fluctuating loads and environmental factors.

As these innovations continue to evolve, we can expect hydraulic pressure relief valves to become increasingly autonomous, enhancing the safety and reliability of hydraulic systems across diverse applications.

Challenges and Opportunities in the Hydraulic Industry for Valve Innovations

The hydraulic industry is at a critical juncture, where innovation in pressure relief valves presents both

significant challenges and exciting opportunities. According to a recent market

research report by MarketsandMarkets, the global hydraulic valves market is projected to reach

$12.10 billion by 2027, growing at a CAGR of 4.2%. This growth

is driven by increasing automation and the need for efficient fluid control systems. However, manufacturers must

navigate several challenges, including the rising cost of raw materials and stringent environmental regulations

that demand sustainable practices.

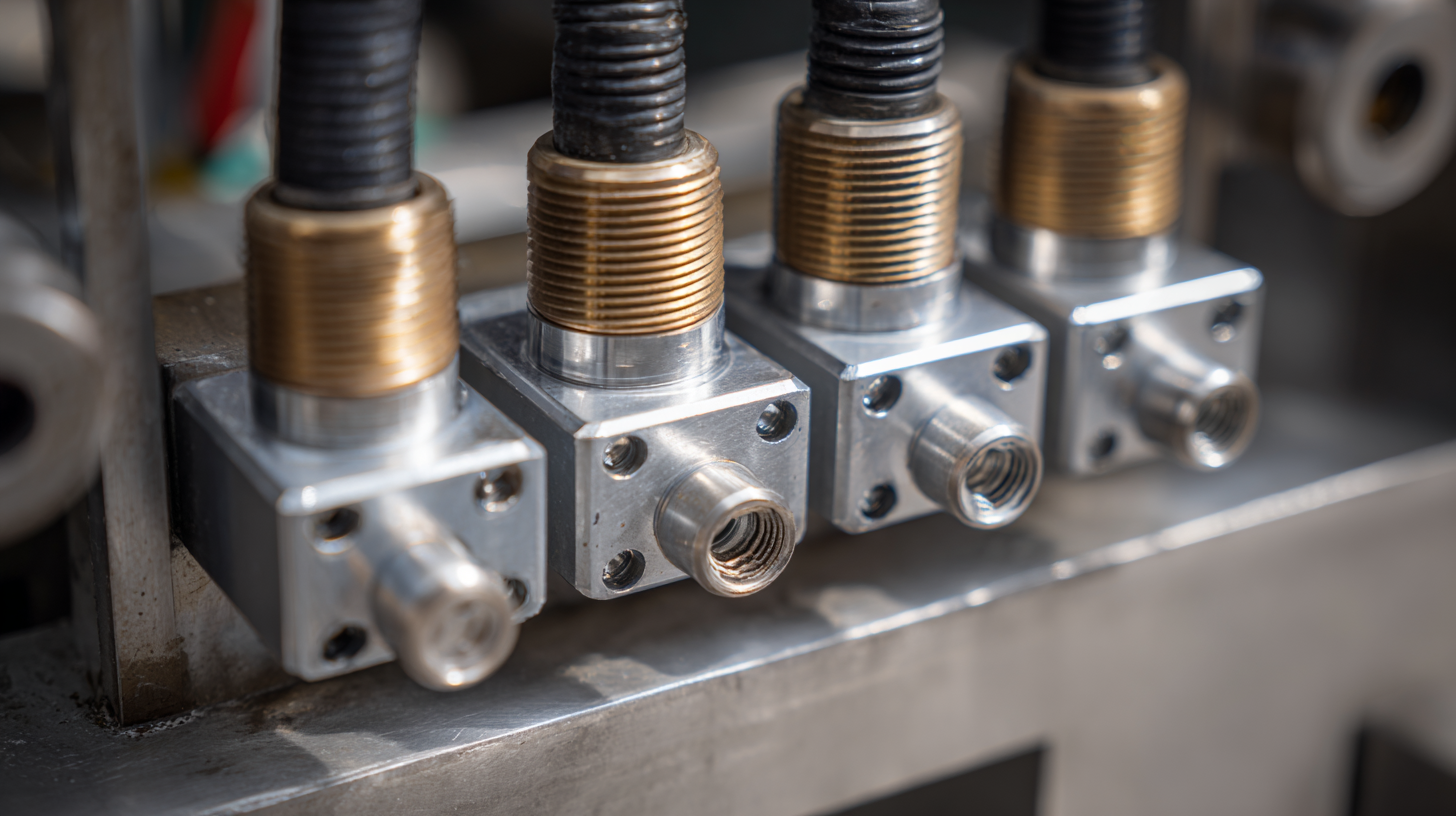

To capitalize on these opportunities, companies should focus on enhancing valve designs through advanced

materials and smart technologies. The integration of

IoT (Internet of Things) has the potential to revolutionize how pressure

relief valves operate, offering real-time monitoring and predictive maintenance capabilities. This can lead to

increased reliability and reduced downtime.

Tip: When considering upgrades

in valve systems, it's crucial to evaluate whether your existing infrastructure can support advanced technologies

without requiring a complete overhaul.

Moreover, addressing market demand for compact and lightweight solutions

can significantly impact product development. As industries strive to improve efficiency and reduce space

constraints, engineers need to innovate designs that do not compromise on safety or performance.

Tip: Collaboration with

cross-disciplinary teams can foster innovative ideas and lead to the creation of next-generation hydraulic

solutions.