How to Effectively Choose the Right Pressure Relief Valve for Your Applications

Selecting the appropriate Pressure Relief Valve (PRV) is critical for ensuring the safety and efficiency of various applications across multiple industries. According to a recent market analysis by Research and Markets, the global pressure relief valve market is expected to reach USD 5.6 billion by 2026, with a significant annual growth rate. This demand highlights the importance of choosing the right PRV to prevent hazardous overpressure conditions in systems ranging from oil and gas to pharmaceuticals. Factors such as valve type, material compatibility, set pressure, and flow capacity play key roles in optimizing performance and longevity. By understanding the specific requirements of their applications and the characteristics of different PRVs, engineers and maintenance professionals can make informed decisions that not only ensure compliance with safety standards but also enhance operational efficiency and resilience in critical processes.

Understanding the Different Types of Pressure Relief Valves and Their Applications

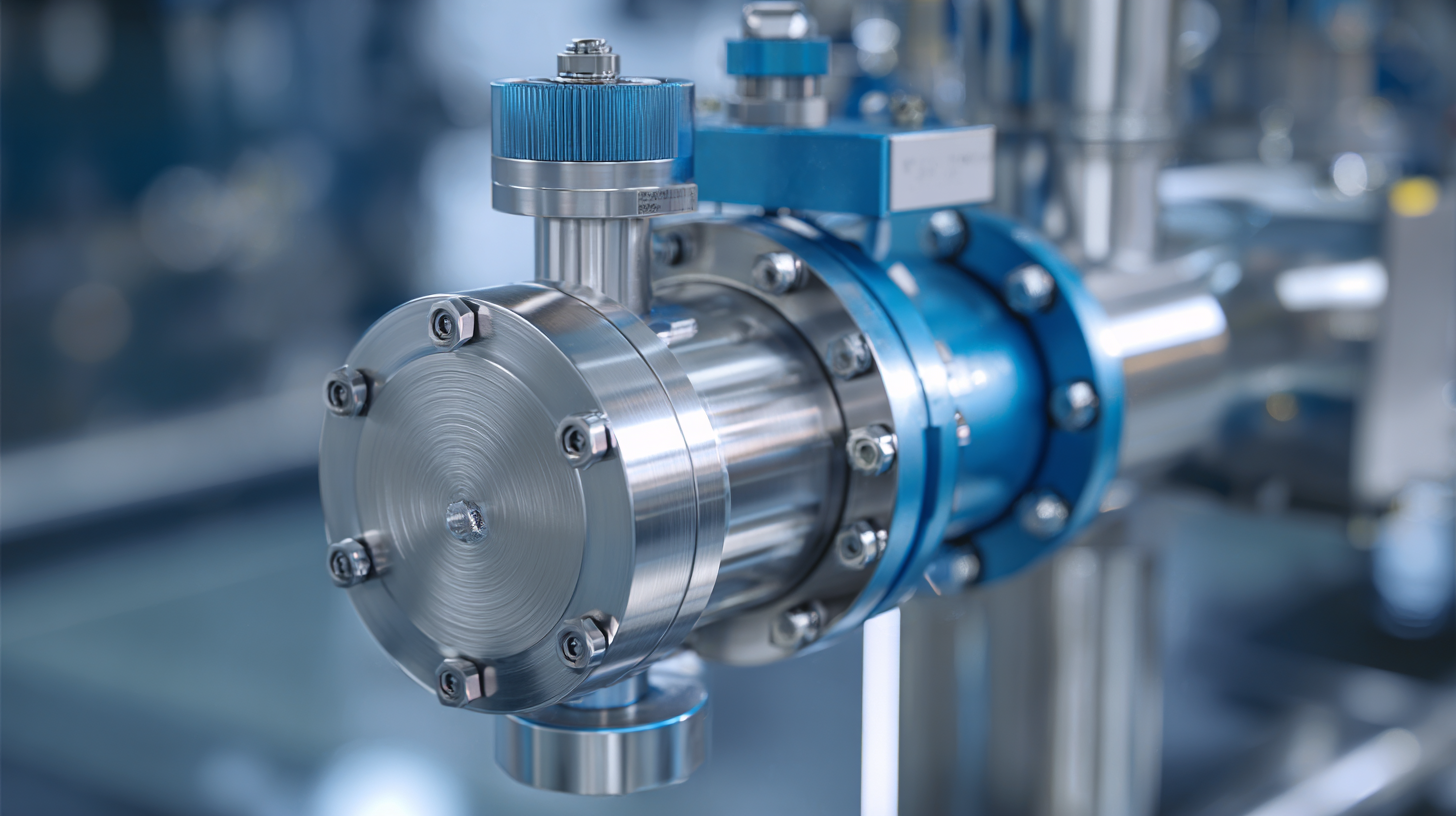

Pressure relief valves (PRVs) are essential components in various industries, ensuring safety and operational efficiency by preventing overpressure conditions. There are several types of PRVs, each designed to suit specific applications. The most common types include conventional spring-loaded valves, pilot-operated valves, and rupture discs. Conventional valves are ideal for general-purpose applications, while pilot-operated valves offer enhanced accuracy and performance in high-pressure systems.

For industrial processes involving gases and fluids, one must select the appropriate valve based on the fluid's characteristics, pressure range, and flow requirements. In waste management or chemical processing, for instance, a high-temperature PRV may be necessary to accommodate the specific conditions. Similarly, in the oil and gas industry, specialty PRVs designed to handle corrosive substances or extreme environmental conditions ensure both safety and longevity in operation. Understanding these differences is crucial for selecting the right PRV that aligns with the unique needs of each application.

Key Factors to Consider When Selecting a Pressure Relief Valve

When selecting a pressure relief valve for your applications, several key factors must be taken into account to ensure optimal performance. First, understanding the specific pressure and temperature conditions of your system is essential. The valve must be able to handle the maximum pressure that could occur during operation, as well as the anticipated temperature range. Failure to select a valve rated for these parameters could lead to malfunction or even catastrophic failure.

Tips: Always refer to the manufacturer's specifications for maximum pressure and temperature ratings. Consider factors such as ambient temperature fluctuations that may affect valve performance.

Another critical aspect is the type of media being handled by the system. Different fluids have varying properties, such as viscosity and chemical reactivity. Ensure that the materials used in the valve construction are compatible with the media to avoid corrosion or wear over time.

Tips: Conduct a compatibility analysis of the valve materials with the fluid being processed. If necessary, consult with manufacturers to identify the best materials for your specific application.

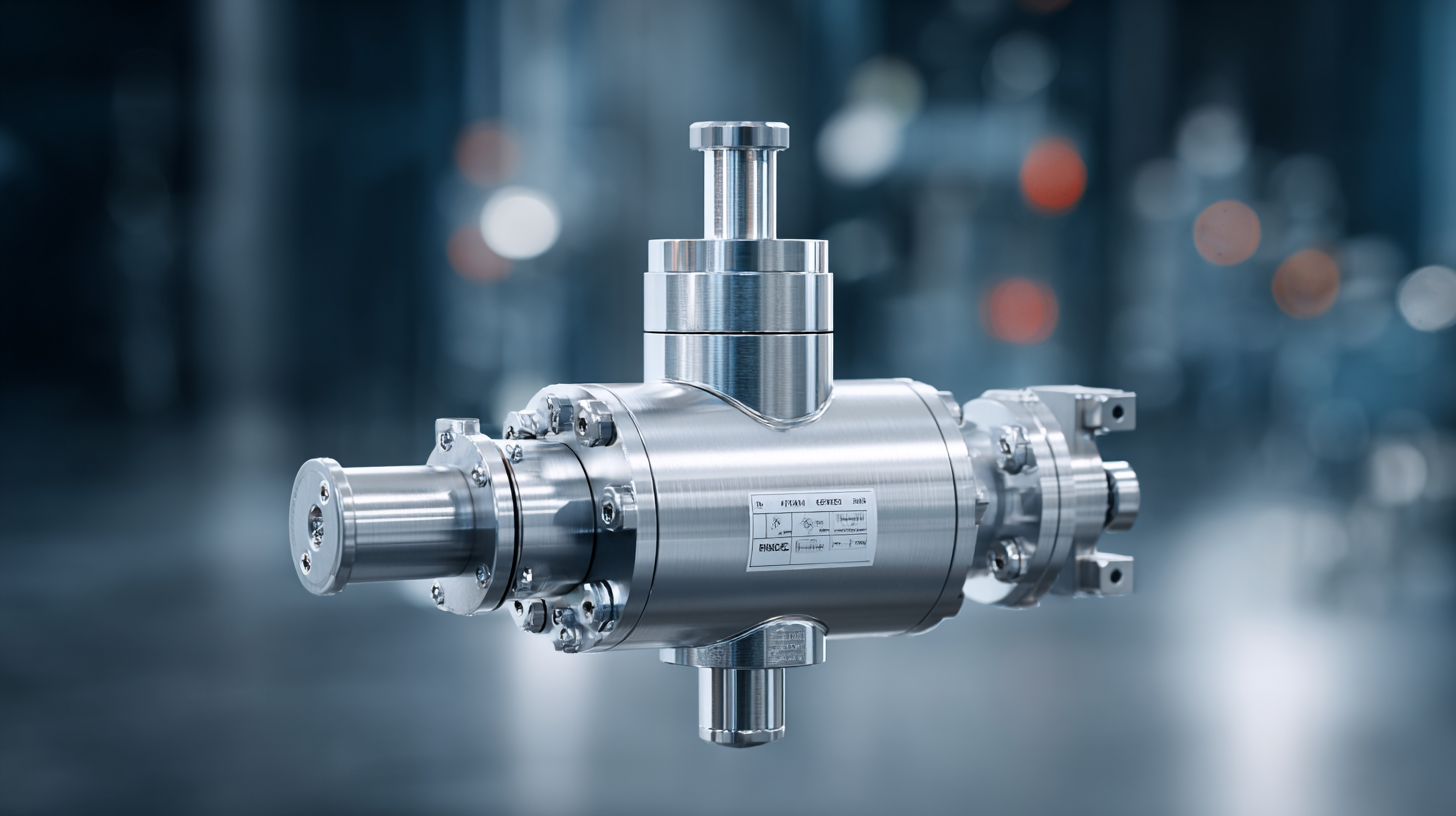

Evaluating Material Compatibility for Pressure Relief Valve Selection

When selecting a pressure relief valve, material compatibility is a critical factor that can significantly influence the valve's performance and longevity. Understanding the operating environment—such as temperature, pressure, and the nature of the media being processed—will help in choosing materials that can withstand these conditions without degradation. For example, if the application involves corrosive fluids, opting for stainless steel or other corrosion-resistant alloys may be essential to maintain integrity and prevent leaks.

Tips for Material Compatibility:

2. Consider the temperature range of your application—high temperatures may require special materials or coatings to avoid deterioration.

3. Investigate if the chosen materials are suitable for the expected pressure conditions to prevent failure under stress.

In addition to chemical compatibility, it is vital to consider the potential for mechanical wear and tear. Valves that operate in high-cycle environments may benefit from robust materials designed to handle repetitive stress. By prioritizing material compatibility, you can ensure that your pressure relief valve will function effectively, providing safety and reliability tailored to your operational needs.

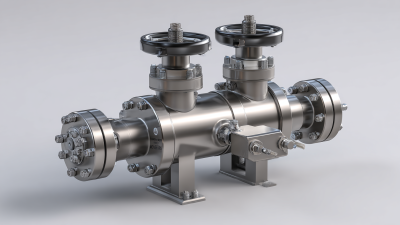

Determining the Correct Sizing and Set Pressure for Your Valve

Choosing the right pressure relief valve (PRV) for your application involves careful consideration of sizing and set pressure. Sizing a valve correctly is crucial to ensure it can handle the maximum possible flow while maintaining system integrity. A valve that is too small may not relieve enough pressure, risking equipment damage, while an oversized valve can lead to operational inefficiencies. Always refer to the manufacturer's sizing guidelines and consider factors such as media type, temperature, and flow rate when making your decision.

Tips: Always gather detailed system data, including pressure readings, flow rates, and energy requirements. This data will help you calculate the necessary valve size accurately. Additionally, consider the installation location and potential environmental factors that may affect valve performance, such as vibrations or corrosive conditions.

Set pressure is another critical factor in PRV selection. It must be determined based on the maximum allowable working pressure of the system and the surge pressures that the valve might encounter. An incorrect set pressure can lead to early valve activation or failure to operate when needed. Therefore, consult with system engineers and adhere to applicable safety standards to ensure the set pressure aligns with operational requirements.

Tips: Conduct periodic reviews of pressure data logs to evaluate whether your current set pressure is optimal. Adjusting set pressure based on operational feedback can significantly improve system safety and efficiency.

Best Practices for Installation and Maintenance of Pressure Relief Valves

When it comes to the installation and maintenance of pressure relief valves (PRVs), adhering to best practices is crucial for ensuring safety and efficiency in various applications. According to a report from the American Society of Mechanical Engineers (ASME), improper installation accounts for approximately 30% of pressure relief system failures. To mitigate this risk, it's vital to follow the manufacturer's guidelines closely when positioning the valve. Ensure that the PRV is installed in a vertical orientation for optimal performance, as this helps to avoid any potential obstructions that could impede the valve’s operation.

Regular maintenance is equally important, with studies from the National Board of Boiler and Pressure Vessel Inspectors indicating that 65% of PRVs surveyed had not been adequately maintained. Routine inspections should include checking for any signs of corrosion or leaks, as well as testing the valve’s set pressure to confirm it operates within specified limits. Furthermore, documenting all maintenance activities can provide valuable insights and help comply with industry regulations. By focusing on proper installation and diligent maintenance practices, operators can significantly enhance the reliability and safety of pressure relief systems in their applications.

Related Posts

-

How to Select the Best Hydraulic Pressure Relief Valve for Your Application

-

7 Best Prv Valve Choices to Enhance Your System Efficiency

-

Understanding the Challenges and Standards in Manufacturing the Best Backflow Preventer Valve

-

Future Innovations in Hydraulic Quick Couplers and Their Advantages in 2025

-

The Future of Advanced Safety Relief Valve Technology

-

Hydraulic Quick Coupler Innovations Showcased at 137th Canton Fair in Guangzhou